|

The onboard software is very simple and

straightforward. There is a main loop that occur every 50 ms, regulated

by a microcontroller timer, that holds all the principal tasks.

The unit has two main state: “Flight Mode” and

“Service Mode”. The Flight Mode is the default state. In this mode the

unit acquires data from sensors, sends telemetry and writes to memory,

if enabled. It is able to receive a limited number of telecommands, and

the TC reception is assured by periodically polling the RX buffer. In

Service Mode, the unit is able to receive long telecommands for

calibrations purposes. In this state the TCs are handled with an

Interrupt Service Routine (ISR) because the RX buffer is not big enough

to receive the entire TC. This causes the telemetry packet to be

corrupted when a TC is sent to the unit, and this is the main reason for

the existence of two modes, “flight” and “service”. While in Service

Mode, the unit can go to the “memory dump mode” state. In this case the

data acquisition is halted until the unit remains in memory management

mode.

There are three interrupt service routines:

-

Real time clock ISR: the routine is entered to

alert the main program that is time to acquire data from sensors. If

20 Hz sampling frequency is selected, the interrupt occurs every

50ms.

-

Capture ISR : is an interrupt that occurs every

rising edge of the incoming signal from magnetometers. It is used to

make frequency measurements of magnetometers output.

-

RX buffer ISR: is a routine that store the

telecommand when received from e-link and makes it available to the

main program for proper handling.

A C-compiler (CCS) has been used to program the

microcontroller.

LowCoINS experiment is able to receive either from e-link serial port or

service serial port several telecommands.

Thermal Control

Telecommands

-

TCs regarding TCU are

needed to switch the heater on and off manually and set the

temperature threshold that trigger the heater switch when the TCU is

in automatic mode.

-

Heater On/Off TCs switch

the heater on/off regardless the actual temperature read on T0 and

threshold temperatures. The Heater will remain in the on/off state

until another on/off TC is received. When “Heater Auto” TC is

received, the control of the heater is restored to the automatic

mode and the heater will be switched on or off accordingly to the

temperature thresholds.

-

TLT & THT (Temperature

Low/High Threshold) TCs can set the temperature thresholds that

trigger the heater switch. The TC is made by a first byte that

specifies if the High or Low threshold has to be modified, the

second byte specifies the value as two’s complement format over 8

bits, the 3rd byte doesn’t care.

Calibration

Telecommands

-

Automatic Bias Null

Calibration

A single-command, automatic bias calibration measures all three

gyroscope output registers, then loads the three bias correction

registers with values that return their outputs to zero (null).

-

Precision Automatic Bias

Null Calibration

Another option for gyroscope calibration, which typically provides

better accuracy, is with the single-command, precision autonull.

This incorporates the optimal averaging time for generating bias

correction factors for all three gyroscope sensors. This command

requires approximately 30 seconds to complete. For optimal

calibration accuracy, the device should be stable (no motion) for

this entire period.

-

Manual Bias Calibration

Using this set of TCs, the user can manually set the bias correction

for accelerometers or gyros. The TC format is as follows: 1st byte:

set the inertial sensor to be calibrated, 2nd & 3rd bytes specifies

the correction value in two’s complement format over 12 bit

(accelerometers) or 13 bit (gyros).

Memory Dump

Telecommands

-

Enter memory dump mode

Makes the unit to enter in memory dump mode; the telemetry

transmission is suspended and a synchronization frame is transmitted

every second.

-

Read All Memory

The entire memory is dumped by the unit.

-

Read Bank N

Only the bank N is dumped.

-

Read bank n, from page

m, for k pages

It allows for read a part of memory bank.

Software for live data recording has been developed

using National Instruments Labview 8.5.

It allows to manage every aspect of LowCoINS

experiment:

·

Live data recording

·

IMU management, sensor sampling rate,

digital filtering, calibration and bias set up

·

Memory management: memory erase, memory

dump

·

Thermal control unit management: allows

for change temperature threshold that triggers the heater also during

the flight, and allows for manual control of the heater.

·

Estimated remaining battery charge

Three different versions have been developed:

1.

Flight mode: to be used for live data recording during the

flight. This version has the ability to send only the TCs needed during

the flight, does not have the TCs for the calibration of the unit.

2.

Service mode: to be used to calibrate the sensors and debug.

3.

Memory Dump: to be used to read the data from the flash memory

and save in the PC.

Below the screenshots of the different software:

In order to have a simpler data

acquisition software every measurement is gathered with the same

sampling frequency, however only nine measurement are downlinked and

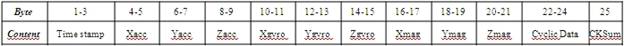

saved to memory with this frequency. The packet of data (frame) to be

stored in the memory is organized as follow:

The last three bytes contain

cyclically ten different data, the resulting update rate for these

measurements is 2 Hz.

Since the flash memories are

organized in 8192 pages of 528 bytes size, each data frame is 24 bytes

long, in this way 22 different frames exactly fit the page memory size

of 528 bytes. Using four Atmel AT45DB321D 32Mbit memories the total

amount of data stored reaches 10 hours of recordings.

The unit begins to record data

in the memory upon reception of the “Start of acquisition” telecommand.

The experiment is connected to

E-link TM/TC module through RS-232 interface. The primary function is to

downlink data collected to the ground station. The telemetry frame

layout is the same as the data frame to be recorded in memory showed

earlier. The only difference is the presence of the byte 25 that

contains a checksum for error detection. The checksum byte is simply the

8 bits sum of the 24 data bytes.

Serial communication is a

standard 9600 bps, 1 bit stop, parity none, no hardware flow control

setup. The protocol used to identify each data frame is the DLE-STX/ETX

protocol. Each data frame starts with two control bytes DLE-STX (10-02

hex) and stops with DLE-ETX (10-03 hex). If in the data frame any byte

is equal to “DLE” (10 hex), then it is sent twice. Adopting these rules,

the start and the end of the frame can be recognised by the ground

software without errors, as DLE-STX and DLE-ETX sequences can only

identify the frame boundary since if they are encountered in the data

frame an extra DLE is present.

|