Holograms can be made on many photosensitive supports. I

tried two of the most diffused holographic supports: Silver

Halide Emulsion and Methylen Blue Dichromated Gelatins. To

finance my expensive hobby of Emulsion Maker, I sold most of my

best Holograms, so here I put only a few Laboratory samples just

for your evaluation.

Transmission holograms

Holograms here pictured are made using a Helium Neon Laser and

red sensitive Homemade Holographic Plates. Thanks to ultrafine silver grains

dispersion and the optimal chemical processing, the final holograms are

perfectly clear and transparent, no traces of Optical Noise (haze) is visible if

viewed using green light too.

Here is another Transmission Hologram. In this picture the Hologram is

illuminated by a low power Green Laser Pointer. The Laser has been

expanded sufficiently to light up all the recorded surface of

the Homemade Holographic Plate. Note how the image is so clear

and haze-free althought viewed in green light, the total absence

of scattering is due to ultrafine silver grains dispersion and

proper chemical treatment.

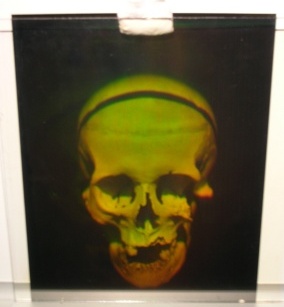

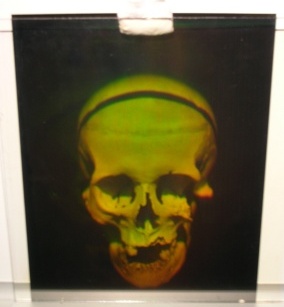

reflection holograms on silver halide plates

The holograms here shown are made on glass plates coated with red

sensitive Silver halide emulsion. A 20mW Heliun Neon Laser is used to expose

the plates using the single beam technique.

As a rule of thumb

using said laser the exposure time for a 230x250 millimiters

homemade holographic plate is about 45 seconds if the single

beam configuration (denisyuk) is chosen.

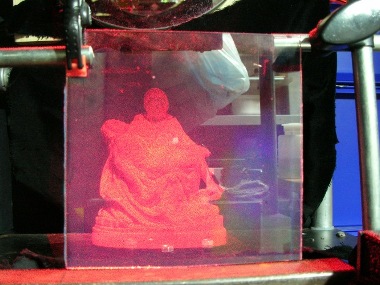

Contact copy of White Light Reflection Holograms made with

homemade holographic plate

(Courtesy of Mauro Melotti -Italy-)

reflection holograms on

methylen blue dichromated gelatins

Diffraction efficiency of Menthylen Blue Dichromated Gelatins (MBDCG)

is simply astonishing. Unfortunally poor shelf-life, low sensitivity of about

50mJ/cm^2, and tricky developing procedures, make this technology poorly

diffused among hobbists.

Using a 20 mW Helium Neon Laser typical exposure

times for 200x200 mm plates are approximately of 20

minutes.

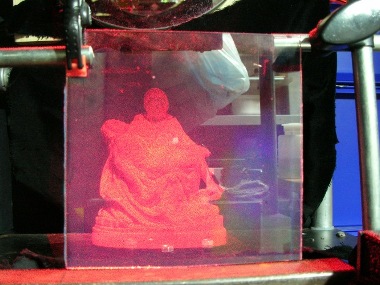

Transmission Hologram. This Holograms can be seen using a

monocromatic light source such as the Laser user to make the

Hologram itself. The Hologram here picturec is made using the Dual

Beams Configuration. Despite the intrinsic limitations of this kind

of hologram, the reproduced image is highly realistic, sharp and

deep.

White Light Reflection Holograms are usually back painted with

acrylic black canned paint. Back painting gives more stability to

the emulsion and protection against scratches and abrasions. Another

important effect of back black painting is a phisical dark

background on which the holographic image can be seen without

interferences from the surrounding environment as walls, light

sources, light reflected by objects. Anyway if the Diffraction

Efficiency of the holographic support if high, the environmental

conditions are almost insignificant as it can be seen on the above

picture.

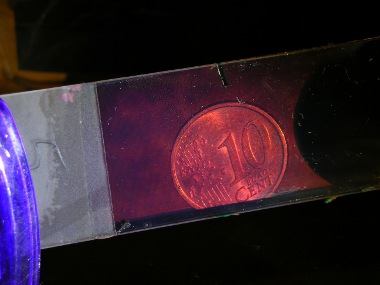

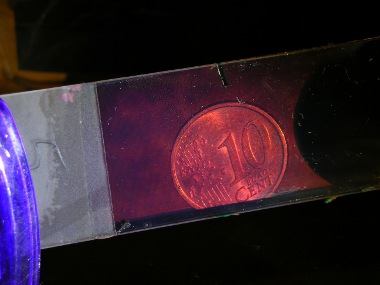

This white light reflection hologran is made exposing the

plate with the light generated by a homemade Ruby Laser. As

discussed in the Laboratory section,

this laser wasn't designed for holographic pourposes, but it

unexpectedly worked when trying to make the hologram of a coin.

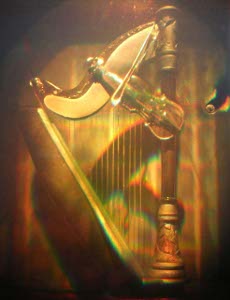

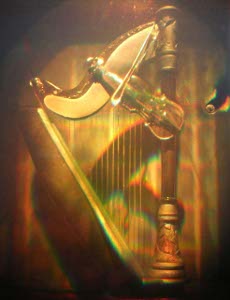

White Light Reflection Hologram made on MBDCG support. In order

to get a so bright image, the 230x180 millimeters plate should be

exposed at least for 18 minutes with a 20 milliwatt helium neon

laser.