|

|

>[]<

|

|

|

|

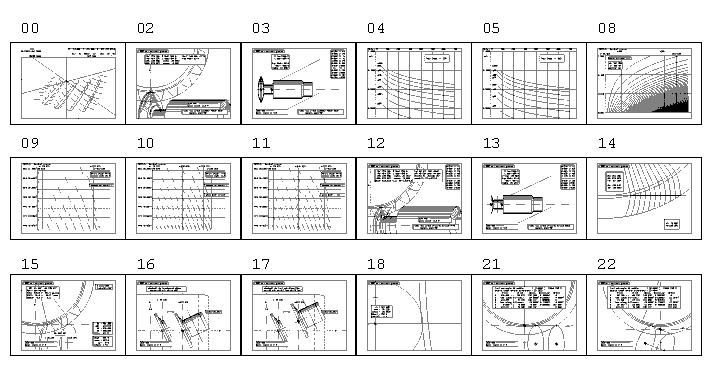

00U

|

* milling paths in continous mode (pinion)

|

|

|

01A

|

* Data sheet of example gear

|

|

|

02A

|

* Previous rough machining wiuth double-cone milling tool: layout

|

|

|

03U

|

* Previous rough machining wiuth double-cone milling tool: tool assembly

|

|

|

04U

|

* Error diagram in continous milling mode, for tool dia=250

due to path step and minimum curvature radius at root

|

|

|

05U

|

* Error diagram in continous milling mode, for tool dia=315

due to path step and minimum curvature radius at root

|

|

|

06A

|

* Optimized planning in multi-cut milling mode, from 2 to 8 cuts

by using 1 only milling tool; maximum over-stock is equal

|

|

|

07A

|

* Optimized planning in multi-cut milling mode, from 2 to 8 cuts

by using 2 milling tool spaced of normal basic pitch;

maximum over-stock is equal

|

|

|

08A

|

* Diagram for hand-calculation of cuts planning in multi-cut mode;

best results when external gap is balanced around external curvature radius

Calculated optimized planning belongs to this diagram

|

|

|

09A

|

* Diagram of otimized planning in multi-cut mode, with proper extra-radius

due to helix ; for use of 1 milling tool

|

|

|

10A

|

* Diagram of otimized planning in multi-cut mode, with proper extra-radius

due to helix ; for use of 2 milling tool , in case krc < 0,50 ;

planning is referred to path of front milling tool;

krc = tool distance / delta curvature radius

|

|

|

11A

|

* Diagram of otimized planning in multi-cut mode, with proper extra-radius

due to helix ; for use of 2 milling tool , in case krc > 0,50 ;

planning is referred to path of rear milling tool;

krc = tool distance / delta curvature radius

|

|

|

12A

|

* Machining layout in internal position = arrive point in continous

milling or innest cut in multi-cut mode

|

|

|

13U

|

* Tool assembly for involute machining, both continous and multi-cut mode

with minimum distance from table to gear edge

|

|

|

14A

|

* Rolling progression : linear increasing of both rotation and tool translation

|

|

|

15A

|

* Extreme positions in continous mode; Feed-fitting value K

and maximum axes speed

|

|

|

16A

|

* Side view of extreme positions, with movement of tool center over

a trasvere plane along X

|

|

|

17A

|

* Side view of extreme positions, with movement of tool center along

tool axe, on machining center or hobbing machine

|

|

|

18A

|

* Side view of milling tool in innest position, with eventual

extra-depth under tangent plane

|

|

|

19U

|

* Calculation of form error: table 1 : 1st value F1 due to path step

and tool diameter

|

|

|

20U

|

* Calculation of form error: table 2 : 2nd value F2 = form error

due to F1 and minimum curvature radius at root

|

|

|

21A

|

* Machining layout in continous mode with tool axe fixed (as by

an ordinary hobbing machine)

|

|

|

22A

|

* Machining layout in continous mode with tool axe oriented as normal

pressure angle : working area is always close to center

|

|

|

23A

|

* DIN allowance for example gear

|

|

|

24A

|

* Rolling area from Da to dNf

|

|

|

25A

|

* Feed-fitting diagram in continous mode + machining time, with 2 tools

for krc < 0,5 : first contact is by front milling tool

and following contact of rear tool makes X-Feed lower

|

|

|

26A

|

* Feed-fitting diagram in continous mode + machining time, with 2 tools

for krc < 0,5 : first contact is by rear milling tool

and whole Feed-fitting is referred to rear milling tool position

|

|

|

27A

|

* Continous milling mode: form error diagram along gear axe

in innest position, WITHOUT extra-depth of tool edge

|

|

|

28A

|

* Continous milling mode: form error diagram along gear axe

in innest position, WITH OPTIMIZED extra-depth of tool edge

|

|

|

29A

|

* Continous milling mode: form error when gear facewidth is

equally shared by machining paths, for tool dia=200 mm

|

|

|

30A

|

* Continous milling mode: form error when gear facewidth is

equally shared by machining paths, for tool dia=250 mm

|

|

|

31A

|

* Mating conditions of example gear pair, with local values

of sliding coefficient and fundamentals

|

|

|

32A

|

* Normal and trasverse profile, with tangent local axes for

tool thickness verify

|

|

|

33A

|

* Rough cut with thin milling tool : layout

|

|

|

34U

|

* Rough cut with thin milling tool : milling equipement

|

|

|

35A

|

* Mating conditions with reference rack

|

|

|

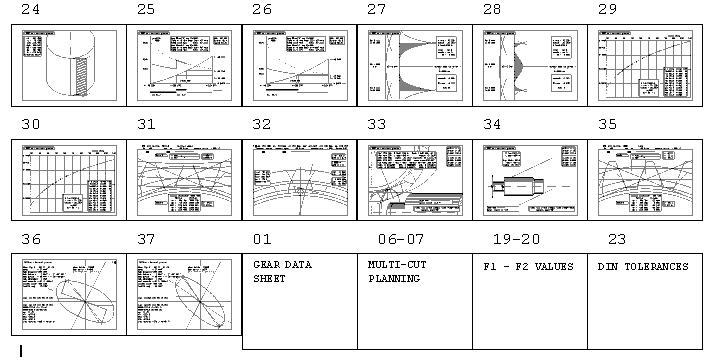

36A

|

* Ellipse diagram of matching gear-hob:

hob helix equal to gear helix L/L or R/R

|

|

|

37A

|

* Ellipse diagram of matching gear-hob:

hob helix reverse than gear helix L/R or R/L

|

|

|

>[]<

|

|